Understanding Stress Corrosion Cracking (SCC)

Understanding the interaction between three variables—mechanical stress, material characteristics, and environmental conditions—is essential for a comprehensive approach to managing the risks associated with SCC and other pipeline threats. This multidimensional approach offers the highest chance of mitigating risks and prolonging the operational life of pipeline infrastructure.

Mechanical Stress on the Pipeline

Mechanical stress on pipelines can arise from various sources such as internal pressure, temperature fluctuations, soil movements, and even tectonic activity. Over time, this stress can cause micro-cracks to form in the pipeline material, which may eventually evolve into more significant stress corrosion cracking (SCC).

Types of Stress

- Tensile Stress: Caused by forces that pull the material apart.

- Compressive Stress: Arises from forces pushing the material together.

- Torsional Stress: Caused by twisting actions.

Stress Concentration Factors

Mechanical stress can often be concentrated around pipeline irregularities such as welds, bends, or junctions. Sophisticated finite element analysis can be employed to understand these stress concentrations better and inform preventive measures.

Monitoring and Mitigation

Advances in strain-gauge technology and remote sensing allow for real-time monitoring of mechanical stress levels, enabling proactive interventions. Regular maintenance and monitoring can mitigate the long-term accumulation of mechanical stress, reducing the risk of SCC.

Material Characteristics of Pipe

The material makeup of the pipeline, including the type of steel, coating material, and even the quality of welds, plays a crucial role in its susceptibility to SCC. Factors like tensile strength, ductility, and hardness are all vital characteristics.

Types of Material

- Carbon Steel: Most commonly used but relatively more susceptible to SCC.

- Stainless Steel: More resistant to SCC but is expensive.

- Composite Materials: Increasingly explored for their resistance to corrosion, but less studied concerning SCC.

Manufacturing Quality

The manufacturing process can introduce imperfections like inclusions or residual stresses that may serve as initiation points for SCC. Therefore, quality control during manufacturing is critical.

Coatings and Linings

Various types of coatings and linings, such as epoxy or zinc, are used to protect pipelines from corrosion. However, improper application can result in gaps or bubbles that may serve as starting points for SCC.

Environmental Conditions Surrounding the Pipeline

The soil and environmental conditions in which a pipeline is buried significantly affect its integrity. Parameters such as soil moisture, pH level, and temperature fluctuations are crucial factors.

Soil Science

- Soil pH: Acidic or alkaline soils can accelerate corrosion processes.

- Moisture Levels: Wet conditions can serve as an electrolyte, facilitating electrochemical reactions leading to corrosion.

- Soil Resistivity: Measures how strongly the soil resists the flow of electric current; lower resistivity often leads to higher corrosion rates.

Climate and Weather

- Temperature Fluctuations: Can lead to thermal expansion and contraction, thereby contributing to mechanical stress.

- Freeze-Thaw Cycles: Can affect the soil's mechanical properties, leading to additional stress on the pipeline.

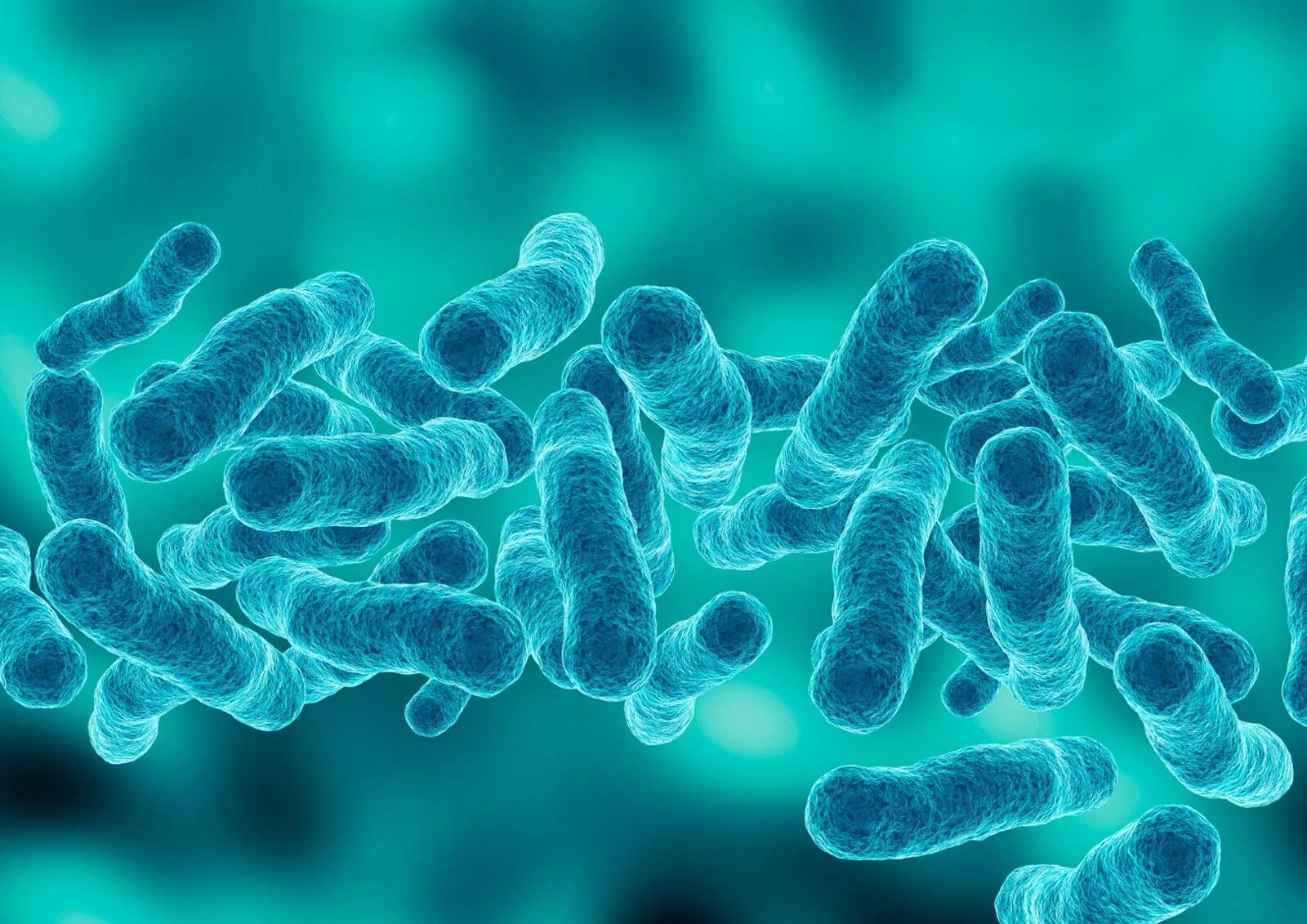

Microbial Influences

Certain microbes can accelerate corrosion through their metabolic processes. These are often referred to as Microbiologically Influenced Corrosion (MIC).

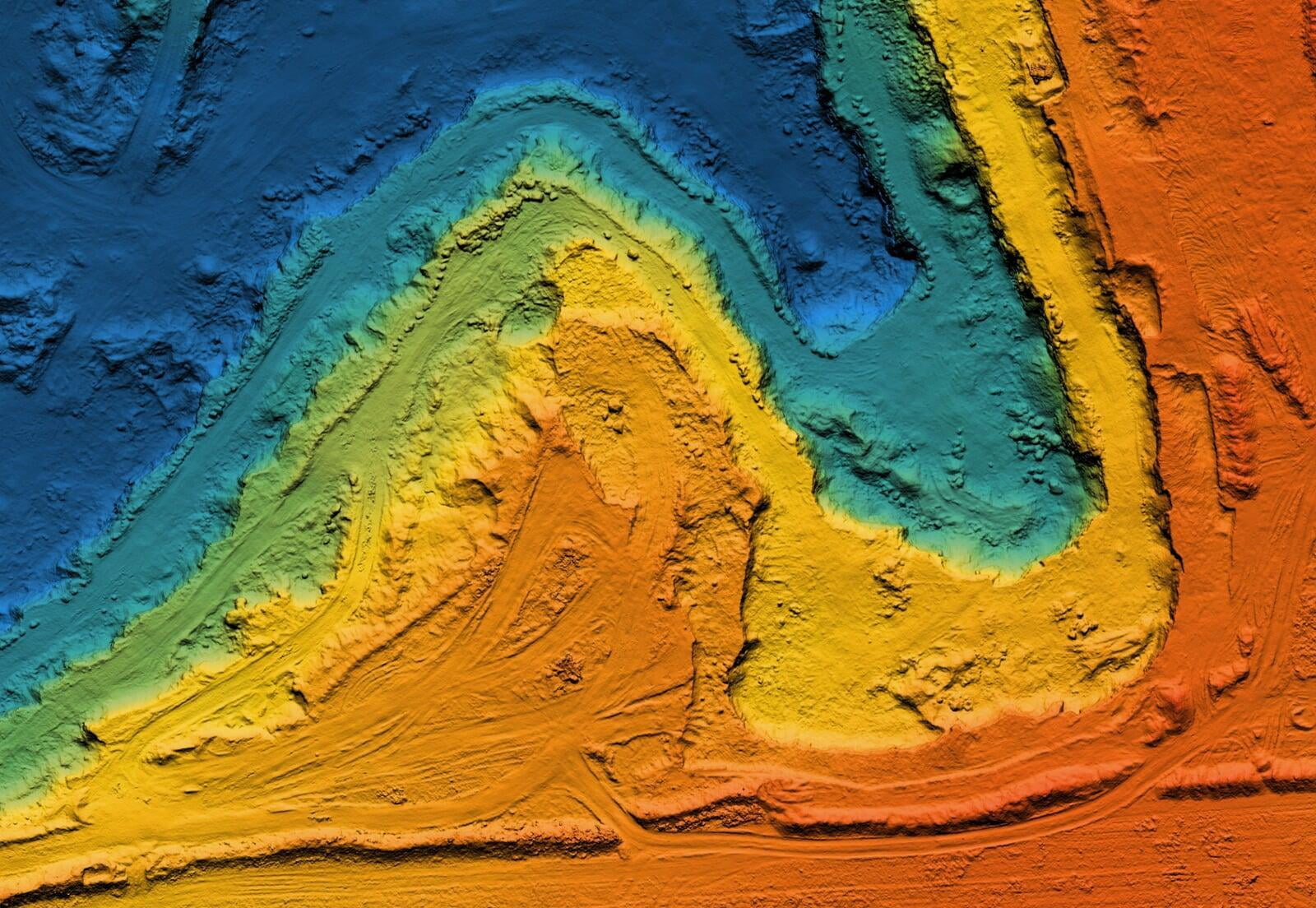

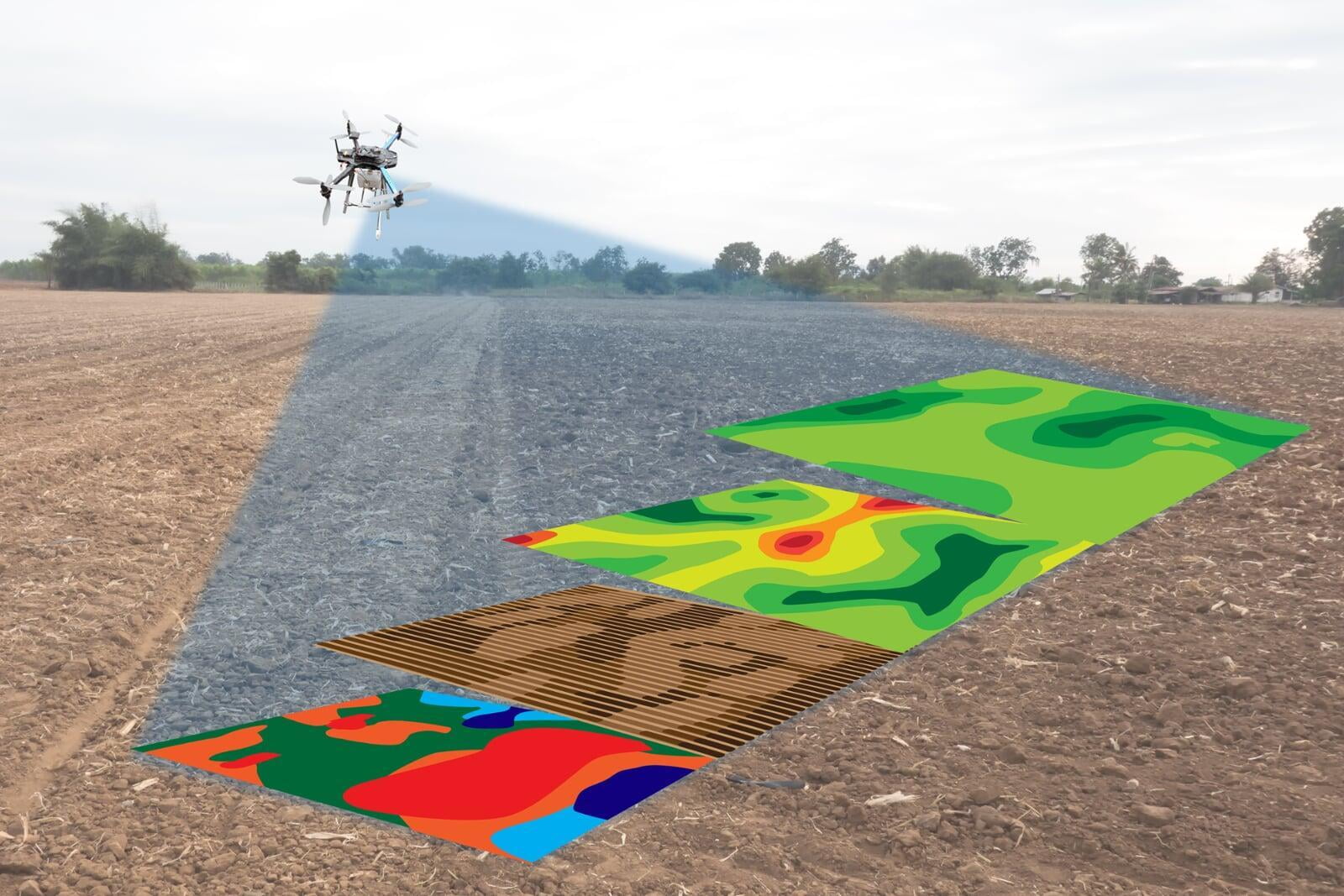

Monitoring Through GIS and LiDAR

Geographic Information Systems (GIS) and LiDAR technology can create high-resolution maps of the pipeline's environmental context, allowing for precise monitoring and predictive modeling of risk areas.

Understanding the interaction between these three variables—mechanical stress, material characteristics, and environmental conditions—is essential for a comprehensive approach to managing the risks associated with SCC and other pipeline threats. This multidimensional approach offers the highest chance of mitigating risks and prolonging the operational life of pipeline infrastructure.